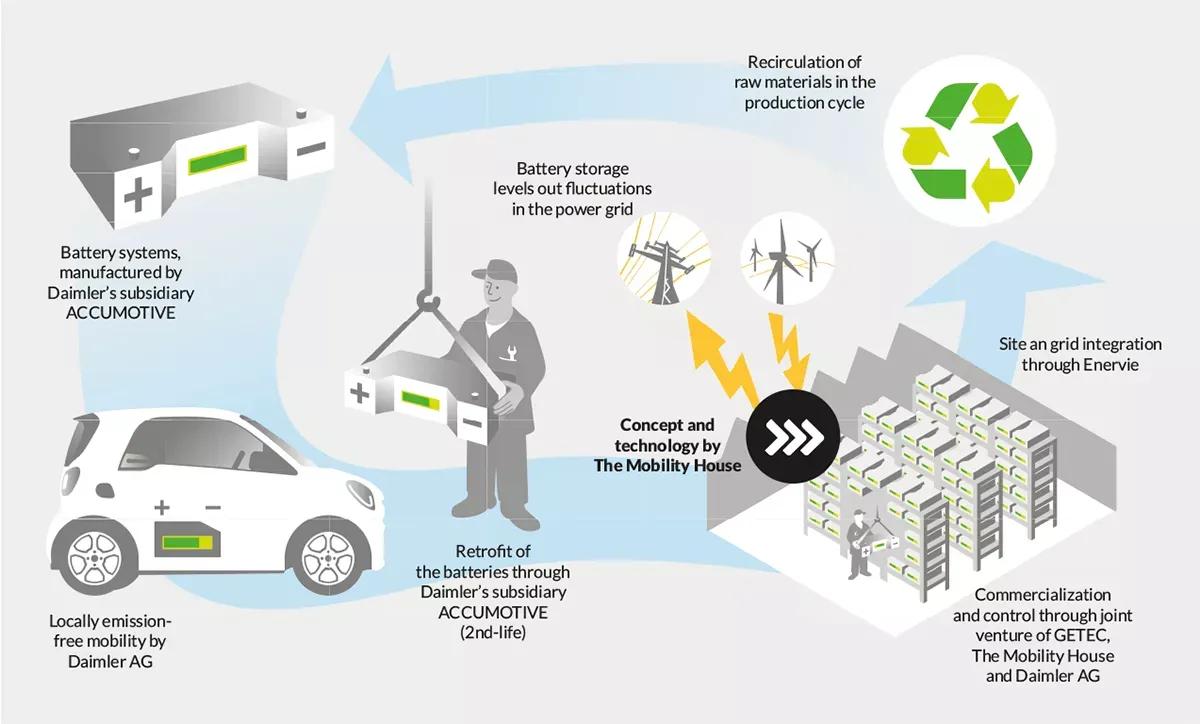

Together with Mercedes-Benz, its subsidiary Mercedes-Benz Energy, GETEC ENERGIE, and Enervie, we have converted an old coal-fired power plant in Elverlingsen into a “living spare parts warehouse”.

Renewable energy instead of coal

In 2018, Mercedes-Benz teamed up with us, GETEC ENERGIE, Enervie, and Daimler subsidiary Mercedes-Benz Energy to commission another innovative battery storage facility. Most of the batteries used in this facility serve as a “living spare parts warehouse” for the third generation of electric Smart cars.

"We are particularly pleased that the coal-fired power plant, which was built in 1912, is becoming a milestone in the energy transition."

Erich Höhne, CEO,

Enervie Group

EV batteries always stay fresh here

To ensure that batteries remain operational, they must be gently charged and discharged on a regular basis. Our technology ensures that this happens.

A spare parts warehouse that earns money

In addition, controlling the storage systems generates revenue on the energy market. The efficient dual use of battery systems improves the environmental balance and life cycle costs of e-mobility.